A proven game changer

Alent Dynamics® patented automatic dynamic drying process has dried over 250 000 batches and saved more than 700 million kWh of electricity.

Customer examples

-

OLWO AG, Switzerland

After converting 5 drying chambers to the Alent Dynamic technology, we were able to directly confirm the promised advantages. End cracks are no longer an issue for us and twisting and discoloration have also been greatly improved. We see significant electricity savings and are happy about a more environmentally friendly drying process. The changeover to the Alent Dynamic drying method was very easy and quick in all chambers.

— Ueli Lädrach, Head of Operations and Production Olwo AG, Worb

-

Holzwerke Ladenburger, Germany

Holzwerke Ladenburger is Germany's largest manufacturer of glulam beams, which now installs the new Alent Dynamic® automated wood drying process in 26 of their kilns in their flagship factory Kerkingen. After this they will have the Alent Dynamic® drying process in over 50 kilns at four factories. The purchase is conducted after careful benchmarking against other solutions in the market.

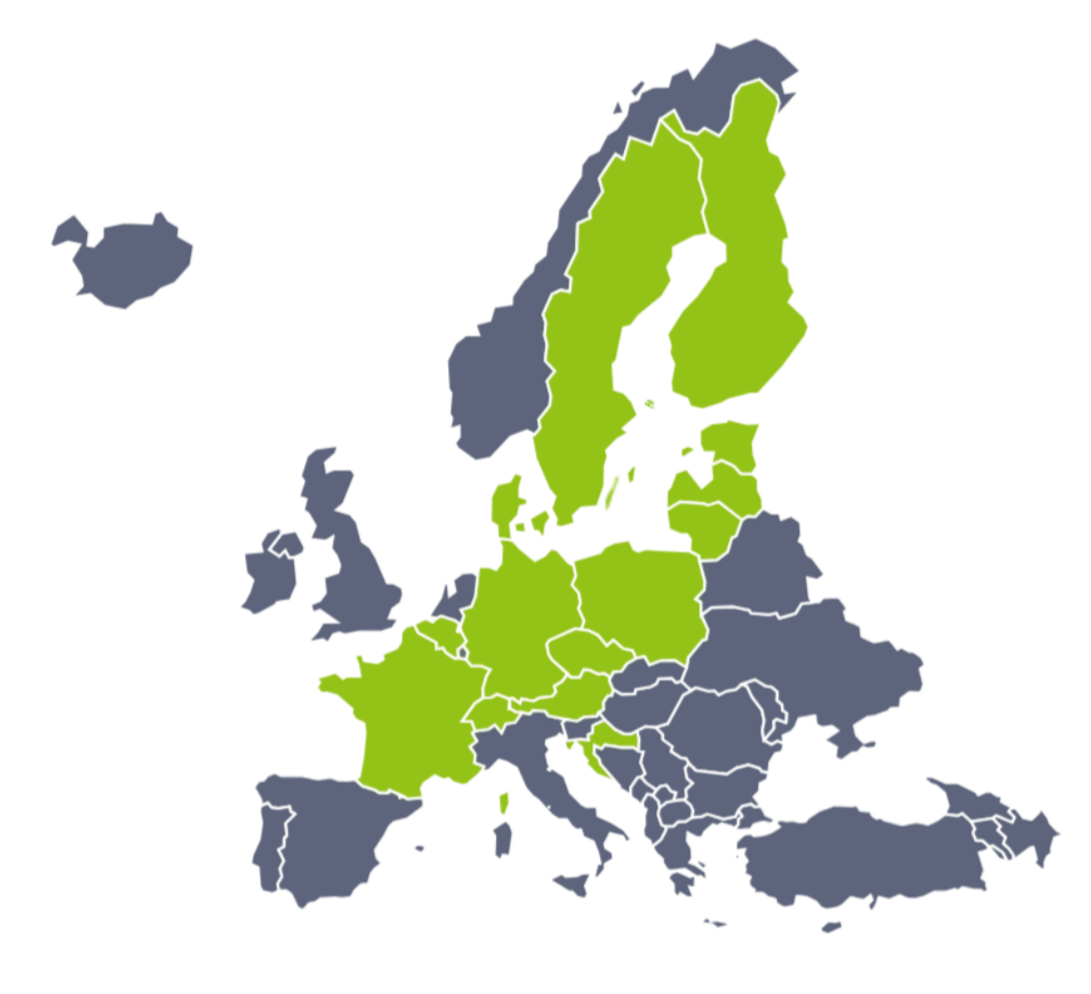

A few of our customers

“With Alent Dynamic Pump we have achieved a 55% reduction in electricity consumption. Additionally, our drying process is 17% faster, increasing our drying capacity. A third key benefit of this method is the significantly reduced cracking and noticeably improved wood quality”

— Baltic Wood, Poland

“Due to increasing prices for electrical energy, we have decided to invest in a more environmental friendly control for our drying process of solid oak. With the patented Alent Dynamic method of interval drying we have reduced the electrical consumtion in average by 50-55%. At the same time, we have now a faster drying process, which in turns, increases production capacity. With all these benefits we can count on a return on investment in the short term.”

— Waldemar Kleniewski, owner Kleniewski Tartak, Poland

“We have seen excellent energy reduction, and reduced quality costs connected to KBS (Kiln Brown Stain).”

— José Pablo Jordan M., Quality Manager at CMPC Maderas, Chile

“With the interval drying method of Alent Dynamic we have reached in average 50% savings in electrical energy and reduced the drying time by 10-15%. We were able to obtain these results while keeping a good drying quality and the moisture spread is in the demanded range. With Alent Dynamic we can unify and have a unique control and statistic report system for all our kilns of different brands.”

— Aivo Tui, responsible for wood drying at Ecobirch AS, Estonia

“After converting the 5 drying chambers to the Alent Dynamic technology, we were able to directly confirm the promised advantages. End cracks are no longer an issue for us and twisting and discoloration have also been greatly improved. We see significant electricity savings and are happy about a more environmentally friendly drying process. The changeover to the Alent Dynamic drying method was very easy and quick in all chambers.”

— Ueli Lädrach, head of operations and production, Olwo AG Worb, Switzerland

“After testing Alent Dynamic® for 3 months, we ordered 16 additional control systems.”

— Christoph Ladenburger, Investment Manager på Holzwerke Ladenburger, Tyskland

“The drying time for Douglas fir has decreased by 25% and electricity consumption by 60%”

— Thomas Dinesen, Owner of Dinesen.

Costumers quotes

“Large energy savings and process safety were what made us decide for Alent Dynamic. In addition to the good drying quality, we are very satisfied with their service. Alent is a valuable partner in wood drying.”

— Theodor Aumann, CEO Asta Holzwerke